How to Become an Auto Mechanic: Salary, Skills, and Career Path

Outline:

– Training routes and entry requirements

– Skills, tools, and credentials that matter

– Daily workflow and specializations

– Pay structures, ranges, and negotiation

– Career growth and future trends

Pathways to Training and Entry Requirements

There’s more than one road into the garage. Some people jump straight into entry-level roles at neighborhood shops; others invest in vocational programs or structured apprenticeships. The core aim is the same: build reliable hands, a diagnostic mindset, and a reputation for finishing jobs safely and on schedule. If your goal is convertirse en mecánico, the first strategic decision is choosing how to balance classroom time with hands-on practice. A realistic plan starts with the basics—safety, tools, and a methodical approach to troubleshooting—before advancing to drivability issues, electrical faults, and modern vehicle networks.

A clear starting playbook can help you avoid costly detours:

– Finish secondary school with strong math, physics, and communication skills; these support measurement, schematics, and customer explanations.

– Explore a local trade program or community training center that includes workshop labs and internships; look for curricula that emphasize diagnostics.

– Consider an apprenticeship under an experienced technician; you’ll earn while learning and observe real-world decision-making.

– Start in a quick-service or tire role to master fundamentals like inspections, fluids, brakes, and torque specs.

Cost matters. Classroom hours teach theory, but much of your learning happens with a multimeter in hand and a service manual nearby. If tuition is a stretch, combine part-time study with paid shop work to keep debt low. Evening or weekend programs can make this viable. Meanwhile, create a simple portfolio: photos of repairs (no customer data), notes on symptoms and fixes, and reflections on what you’d do differently next time. This record shows employers your growth and integrity. Finally, treat punctuality, cleanliness, and tool care as non-negotiables—small signals that you’re dependable around expensive equipment and safety-critical systems.

Skills, Tools, and Credentials Employers Notice

Successful technicians blend mechanical craft with systems thinking. Engines and brakes still matter, but today’s vehicles carry dozens of control modules, sensors, and communication lines. You’ll need to read wiring diagrams, interpret scan data, and confirm failures with tests—not guesses. Hiring managers care less about buzzwords and more about how you isolate root causes. Whether you’re eyeing independent shops or fleet maintenance, the skill stack below helps you compete for trabajos de mecánico de coches and negotiate a fair starting number for the salario de mecánico you bring to the table.

Core capabilities to build in your first two years:

– Mechanical: fasteners, torque sequences, seals, bearings, suspension geometry, and brake hydraulics.

– Electrical: voltage drop testing, continuity checks, parasitic draw diagnosis, relay logic, sensor plausibility, and grounds.

– Diagnostics: symptom-to-system mapping, service information search, freeze-frame analysis, and repair verification.

– HVAC: refrigerant handling, leak detection, blend door operation, and pressure/temperature relationships.

– Drivetrain: clutches, torque converters, CV joints, differential basics, and shift strategies.

– Emerging tech: hybrid/EV safety, high-voltage isolation principles, thermal management, and ADAS calibration fundamentals.

On tools, start lean and expand as you specialize. A reliable torque wrench, insulated gloves for high-voltage work, a quality multimeter with min/max logging, and a mechanical stethoscope cover many situations. For software, you’ll encounter scan interfaces ranging from basic code readers to advanced platforms; learn how to extract data, create a test plan, and document results without relying solely on automatic part recommendations. Credentials can strengthen your case with employers, especially where formal proof of competence is valued. Look for recognized exams in brakes, electrical, engine performance, and hybrid systems, but treat certificates as complements to field-tested troubleshooting. Round that out with clear writing—concise repair orders reduce comebacks and build customer trust.

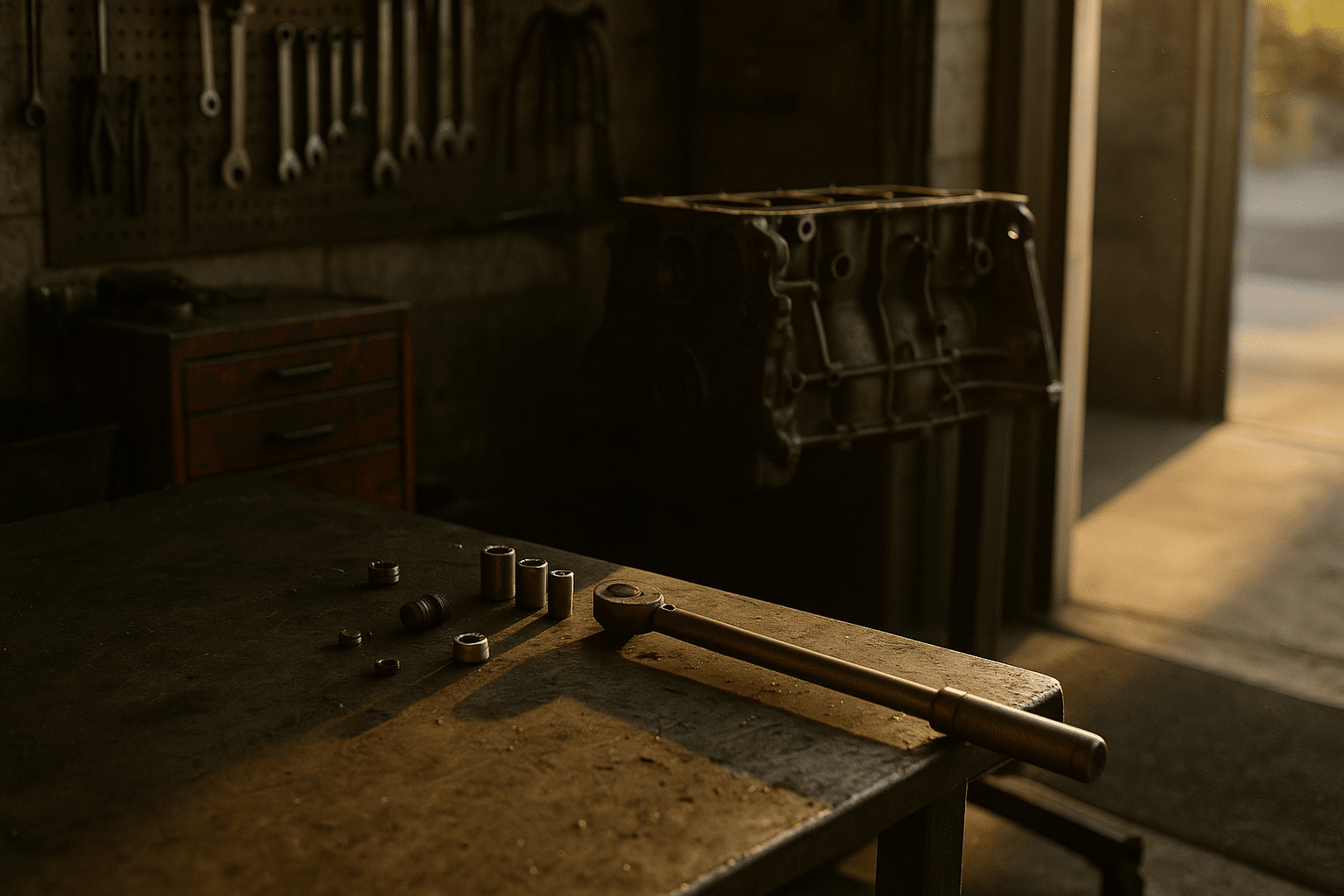

Inside the Workshop: Daily Workflow and Specializations

Once you’re on the floor, rhythm matters. Mornings often begin with a stack of repair orders, quick inspections, and a conversation with the service writer about priorities. You’ll juggle simple maintenance alongside deeper diagnostics, making judgment calls about which vehicle needs road testing, which needs a smoke test, and which needs a longer electrical workup. If your plan is to convertirse en mecánico who’s in demand, learn to triage: confirm the complaint, check for basics (battery, fuses, obvious leaks), and only then dive into complex systems. This deliberate, repeatable flow reduces wasted parts and time.

Specialization can accelerate your career and earning power:

– Drivability/diagnostics: intermittent misfires, lean trims, and ghost codes; you’ll live by scope traces and voltage drops.

– Steering/suspension: alignments, noise/vibration/harshness tracking, and chassis geometry; ideal if you like test drives and measurable results.

– Brakes and safety systems: ABS stability faults, hydraulic imbalances, and rotor diagnostics; precision and documentation rule here.

– HVAC and thermal management: from condensers to electric compressors; seasonality can keep your schedule balanced.

– Hybrid/EV systems: high-voltage safety, isolation testing, battery health, and inverter cooling; this niche is expanding fast.

– Fleet and heavy service: uptime-focused maintenance, standardized procedures, and data-driven interval planning.

Communication binds it all together. Clear notes help advisors set expectations and authorize the right tests; honest timelines prevent misunderstandings. Over time, you’ll develop intuition about pattern failures, but anchor that instinct with measurements. After a fix, verify with a road test and post-repair scan, then explain the root cause in plain language. Shops reward techs who minimize comebacks, protect customer vehicles, and share knowledge with teammates. Those habits create trust—and trust turns into complex assignments that build mastery.

Pay, Perks, and How Compensation Really Works

Understanding pay models is essential before you accept any offer. Employers may use hourly, salary, or flat-rate systems (pay per billed hour) and sometimes a hybrid. Hourly pay provides stability; flat-rate can increase earnings if workflow and parts availability are steady. Benefits—health coverage, paid time off, tool stipends, training budgets—add meaningful value beyond the number you see on a paycheck. When researching the salario de mecánico, compare offers apples-to-apples by converting everything to an estimated yearly total that includes likely overtime and realistic efficiency.

What do ranges look like? Figures vary widely by region and specialization. In many parts of the United States, median annual pay often lands in the low-to-mid $40,000s, with experienced diagnosticians and high-efficiency technicians reaching $60,000–$80,000 or more in busy urban markets. Across Western Europe, medians commonly fall around €25,000–€38,000, with major metros paying higher. In parts of Latin America, annual earnings for full-time technicians frequently range from about US$6,000 to US$15,000, with increases tied to fleets, premium services, or advanced diagnostics. These are broad snapshots; cost of living, shop type, and workflow can shift outcomes considerably.

Factors that move your earnings up:

– Specialization in diagnostics, hybrid/EV, or ADAS.

– Documented low comeback rate and strong customer feedback.

– Efficiency supported by well-maintained tools and a tidy bay.

– Willingness to handle weekend or evening shifts when demand spikes.

– Training that lets you take on complex tickets others avoid.

Negotiation starts with evidence. Track your billed hours, first-time fix rates, and training milestones. Bring a clean comparison of total compensation from similar shops in your area, including commute time and schedule flexibility. If a shop runs on flat-rate, ask about parts delivery speed, dispatch practices, and average weekly billed hours—these determine whether your skills translate to income. Finally, revisit pay after new certifications or measurable improvements, and be open to structures that reward growth without overpromising.

Advancement, Business Paths, and the Future of Wrenches

Automotive service is changing, and that’s an opportunity. As vehicles gain more software, sensors, and electrified components, technicians who blend mechanical craft with digital fluency rise quickly. For those targeting trabajos de mecánico de coches today, building proficiency with scan data interpretation, high-voltage safety procedures, and ADAS calibration will open doors tomorrow. Advancement doesn’t require a single blueprint; it’s a set of choices you align with your interests, finances, and lifestyle.

Common ladders to climb:

– Senior technician/diagnostician: the go-to problem solver for intermittent faults and complex drivability issues.

– Shop lead or foreman: assign work, mentor juniors, enforce quality and safety, and coordinate parts and timelines.

– Service advisor or manager: translate technical findings into clear estimates, manage customer relationships, and oversee workflow.

– Mobile specialist: take diagnostics, programming, or maintenance to fleets and residential driveways.

– Educator or trainer: teach at local programs or lead in-house workshops, shaping the next generation.

If you eventually run your own bay, start small and document everything: parts warranties, torque logs, and pre-/post-inspection photos. Focus on a niche—brakes and steering, diagnostics-only, hybrid systems—so your marketing is clear and your equipment purchases stay targeted. Keep overhead lean, build partnerships with local parts distributors, and schedule follow-up checks to catch issues early. Remember, consistent processes reduce mistakes and protect margins. As technology evolves, keep learning: battery management strategies, thermal control, and safe handling of high-voltage components. The goal isn’t to chase every trend but to choose the ones that strengthen your services. With steady practice, thoughtful investments, and respect for safety, trabajos de mecánico de coches can grow into a resilient, future-ready career.